Views: 0 Author: Site Editor Publish Time: 2025-05-14 Origin: Site

Cold rolling is a crucial process in the metalworking industry, used to transform metal into desired shapes and sizes. Have you ever wondered how metals are made smoother, thinner, and more uniform? Cold rolling is the key to achieving these qualities. By the end of this post, you’ll learn why cold rolling is vital for producing high-quality metal products like cold rolled coils and how it contributes to their durability and performance.

In this article, we’ll explore the cold rolling process in detail, its benefits, and its applications in various industries. Whether you’re looking for Cold Rolled Coil products for your business or simply curious about the technology, you’ll find valuable insights here.

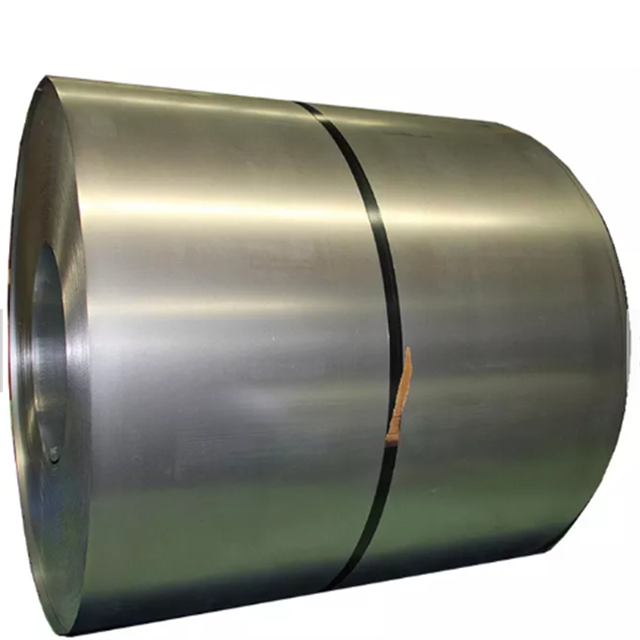

Cold rolling refers to the process of shaping metal at room temperature by passing it through rollers. Unlike hot rolling, which is done at high temperatures, cold rolling involves compressing the metal without heating it, leading to a much finer finish. This technique results in metal products that have a smooth, uniform surface with enhanced strength.

● Step 1: Preparation of the Metal

○ Initially, the metal is cleaned to remove any surface contaminants like oil or dirt. This ensures that the metal passes through the rollers smoothly and evenly.

● Step 2: Rolling the Metal

○ The metal is passed through rollers under high pressure. As it passes through, it becomes thinner and gains a uniform texture.

● Step 3: Cooling and Final Inspection

○ After rolling, the metal is cooled and inspected for defects or irregularities. At this stage, adjustments can be made to ensure the metal meets the required specifications.

This process results in products like cold rolled coils, which are widely used in manufacturing, automotive, construction, and many other industries.

Cold rolling offers several benefits that make it a preferred method for processing metals, especially for industries that require precise and high-quality materials.

Cold rolling increases the hardness and tensile strength of metals, making them more durable. The process improves the grain structure, providing metal products with better strength and resistance to wear and tear.

The smooth surface finish produced by cold rolling makes it ideal for applications that require aesthetic appeal or precise dimensions. This makes cold rolled coils perfect for products like appliances, automotive components, and decorative items.

Cold rolling allows for precise control over the thickness of the material. The resulting metal is more uniform and consistent in thickness compared to other methods, making it suitable for applications that require exact specifications.

Though it may seem like an advanced process, cold rolling is often more cost-effective in the long term. The improved strength and uniformity of the material reduce the need for further processing, saving time and resources.

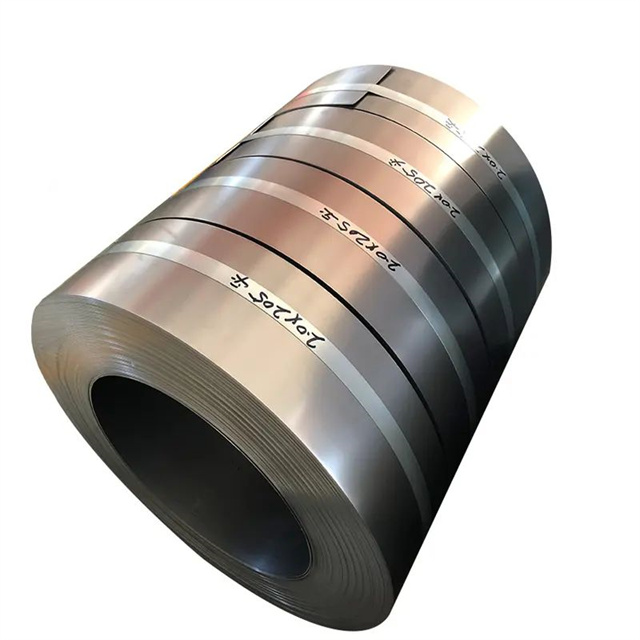

Cold rolled coils are versatile and can be used in various industries. Below are some of the most common applications of cold rolled coils:

Cold rolled steel is widely used in the automotive sector for manufacturing car bodies, chassis, and other components. The enhanced strength and smooth finish make it ideal for creating parts that need to withstand heavy usage.

Cold rolled steel is used in structural applications such as beams, columns, and supports. Its high tensile strength makes it perfect for construction projects requiring durability and stability.

Products like refrigerators, washing machines, and air conditioners require components that are both durable and aesthetically pleasing. Cold rolled coils are often used to manufacture parts such as panels, casings, and frames in these appliances.

From refrigerators to ovens, cold rolled steel is a preferred choice for creating strong, long-lasting home appliances. The smooth finish and precise dimensions allow for seamless integration into these products.

As a leading supplier of cold rolled steel, China Hongkun Supply Chain Co., Ltd. ensures the highest quality cold rolled coils for various industries. With a focus on precision, durability, and customer satisfaction, the company provides tailored solutions that meet the exacting needs of businesses across sectors.

By choosing products from China Hongkun Supply Chain Co., Ltd., customers can be assured of receiving cold rolled materials that meet global standards and are suited to their specific requirements.

When selecting cold rolled products for your business, it's essential to consider the following factors:

Ensure the product meets the specific requirements for your application, such as thickness, surface finish, and strength.

Cold rolling improves the material's durability, but it’s important to assess the quality control measures in place to ensure consistent performance.

While cold rolled products may be more expensive upfront compared to other types of steel, the long-term benefits such as durability and reduced need for additional processing make it a cost-effective choice.

Cold rolling is a vital process in the production of high-quality metal products, especially cold rolled coils, which are crucial for a wide range of industries, from automotive to construction. With its advantages of improved strength, uniform thickness, and superior finish, cold rolling plays a key role in shaping the metals that power our modern world.

If you're looking for top-notch cold rolled materials, China Hongkun Supply Chain Co., Ltd. offers premium products designed to meet the highest industry standards. Don’t hesitate to explore their offerings and find the perfect cold rolled solutions for your business.

A: Cold rolling is done at room temperature and results in a smooth finish and greater strength, while hot rolling is performed at high temperatures and is typically used for thicker materials.

A: Cold rolled coils are widely used in automotive, construction, electrical appliances, and consumer goods industries due to their durability and precision.

A: Consider factors such as material specifications, durability, and cost-effectiveness when selecting cold rolled coils for your application.