Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

What exactly is MS chequered plate? Whether you're involved in construction, automotive, or industrial sectors, you've likely come across the term "chequered plate." This material plays a critical role in various applications due to its unique properties and versatility. Checkered plates are a staple in industries requiring robust, durable materials that can withstand heavy foot traffic, mechanical stress, and harsh environmental conditions.

In this article, we'll explore what MS chequered plates are, their manufacturing process, advantages, and the diverse applications they serve. If you're wondering how checkered plates can enhance your projects, read on to discover why this material might be the perfect fit for your needs.

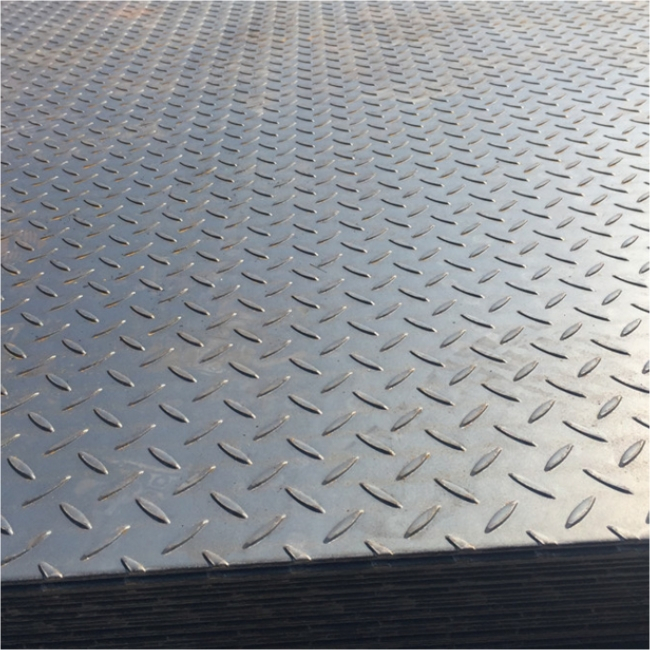

MS stands for mild steel, a low-carbon steel known for its strength, durability, and ease of fabrication. MS chequered plates, also known as checkered plates, are flat metal sheets with raised patterns, typically diamond-shaped, that enhance traction and provide a slip-resistant surface. These plates are widely used in a variety of industries due to their excellent load-bearing capacity and anti-slip features.

1. Material Selection: The process begins with the selection of mild steel, which is then heated to a specific temperature.

2. Rolling: The heated steel is passed through rollers to flatten it and reduce its thickness.

3. Pattern Formation: A patterned roller is used to imprint the characteristic raised diamonds onto the steel's surface. This step adds the slip-resistant feature that checkered plates are known for.

4. Cooling: The plates are then cooled to room temperature before being cut to size and prepared for shipment.

The ability to create these raised patterns on MS chequered plates makes them ideal for applications where safety and durability are essential.

The most prominent feature of MS chequered plates is their slip-resistant surface, which reduces the risk of slipping, especially in wet or oily conditions. This is why they are often used in environments with heavy foot traffic or where safety is a concern.

MS chequered plates are made from mild steel, which offers excellent strength. The raised pattern adds extra rigidity to the plate, making it suitable for heavy-duty applications. This makes checkered plates ideal for use in machinery, floors, stairs, and even bridges.

Mild steel is relatively easy to work with compared to other metals. MS chequered plates can be easily welded, cut, and formed to meet specific project requirements, making them a versatile option for different applications.

While mild steel is not as resistant to corrosion as stainless steel, MS chequered plates can be coated with anti-corrosive treatments such as galvanization or painting. These coatings help extend the plate's lifespan and ensure it maintains its durability even in harsh environments.

One of the main reasons MS chequered plates are widely used is their cost-effectiveness. Mild steel is generally more affordable than other steel types, making checkered plates an economical choice for many industries, without compromising on quality and strength.

MS chequered plates find their applications in a wide range of industries due to their unique properties. Here are some of the most common uses:

In construction, MS chequered plates are used in the creation of stair treads, flooring, walkways, and platforms. The slip-resistant surface makes them an excellent choice for buildings and structures where safety is a priority.

In the automotive industry, checkered plates are commonly used for vehicle floors, especially in trucks and transport vehicles. The durability and anti-slip properties are essential for heavy-duty vehicles that transport goods or people.

Due to their ability to resist corrosion, MS chequered plates are often used in marine environments, including the construction of ships, docks, and offshore platforms. The plates help prevent slipping and provide a secure surface in areas with high moisture levels.

Industrial settings, such as factories and warehouses, often use checkered plates for flooring. Their resistance to wear and tear, along with the ability to withstand heavy machinery, makes them a practical choice for high-traffic areas.

In facilities with high pedestrian traffic, MS chequered plates are used for constructing staircases and elevated platforms. The raised pattern improves grip, ensuring that people can walk safely, even in wet or oily conditions.

The most significant advantage of checkered plates is their ability to improve safety. Their slip-resistant surface helps prevent accidents in areas where water, oil, or other substances might cause people to slip.

With proper maintenance, MS chequered plates have an extended lifespan. They can endure harsh conditions without deteriorating, making them a great long-term investment for construction and industrial projects.

Whether you need checkered plates for flooring, vehicle decking, or structural components, they are a versatile material that can be used in various industries. They are available in different sizes and thicknesses, allowing you to select the right option for your specific needs.

Compared to other high-strength materials like stainless steel, MS chequered plates are more affordable. This makes them a great option for projects that need a high-performance material at a lower cost.

MS chequered plates are a reliable, versatile, and cost-effective material that offers a range of benefits for various industries. Their slip-resistant surface, high strength, and durability make them a popular choice for applications that require both safety and performance. Whether you're looking to use checkered plates for construction, automotive, or industrial purposes, their value is unmatched.

By choosing MS chequered plates, you're investing in a material that will provide lasting performance, improved safety, and cost-efficiency.

A: The primary purpose of MS chequered plates is to provide a slip-resistant surface, making them ideal for use in high-traffic areas, stairs, and industrial flooring.

A: Yes, MS chequered plates are made from mild steel, which is easy to cut, weld, and form, making them highly versatile for different applications.

A: MS chequered plates are more cost-effective than stainless steel plates, but they require protective coatings for outdoor or corrosive environments, whereas stainless steel is naturally corrosion-resistant.

A: MS chequered plates are used in various industries, including construction, automotive, marine, industrial flooring, and manufacturing, for their strength, durability, and slip-resistant properties.